Improved Pipelay to 3000m and Beyond

Verderg Pipe Technology Ltd (VPTL) continues to improve deep water pipeline engineering with the patented “Sag Bend Buoyancy System” solution. The company offers an ever-growing suite of proprietary advances in Design Analysis methodology, Quality Control testing and Pipelay techniques and can now help take economically-sized pipelines into 3000m deep water and beyond with this development.

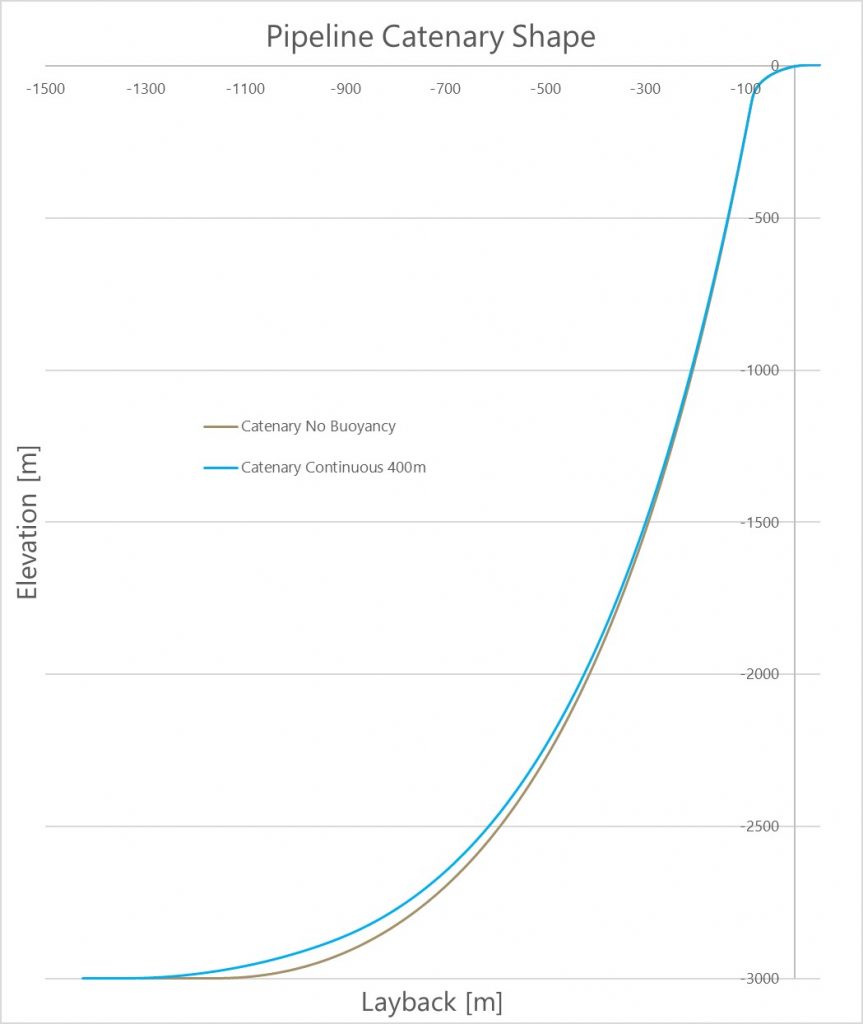

Throughout 2021 – 2022, VPTL continued to listen to leading voices from within the industry, developing answers to the problems they encountered with pipelay into ever-increasing water depths. VPTL’s Ring Testing technologies permit a substantial increase to the depth at which a deepwater pipe has acceptable resilience against hydrostatic collapse in situ on the sea bed. However, concerns were expressed that the pipe could actually be more vulnerable during installation where it bends towards the horizontal in what is called the Sag Bend, just above the sea bed. Although the hydrostatic pressure in the Sag Bend is slightly lower than at the sea bed, there are additional bending stresses, leading to the concern.

Sag Bend stresses have always occurred just above the sea bed even in shallow and medium water depths. They have historically been addressed by increasing the horizontal tension that the lay vessel imparts to the pipe using its anchor cables in shallow water, or thrusters in deeper water. The perception of 3000m+ marine pipeline installation as a barrier or limit is actually a more nuanced cost-benefit discussion. This centres on competing economics of reducing the pipe diameter, thus reducing the product throughput, set against further increasing the already substantial lay vessel thrust capacity, as installation into water depths of 3000m and beyond are contemplated.

Sag Bend Buoyancy System

VPTL developed and patented a direct solution to this notional pipelay depth barrier called the “Sag Bend Buoyancy” system, or SBB for short. SBB features a small number of buoyancy aids that support the Sag Bend during very deep water installation. These reduce the curvature of the Sag Bend to within acceptable limits and maintain code compliance of the pipeline during installation.

Most recently, VPTL commissioned an independent leading design house to investigate the efficacy of the SBB concept and they have validated its potential. This now takes the Sag Bend issue off the table completely, opening up the potential for installation of economically-sized pipelines up to and beyond 3000m with existing installation equipment.