Pipeline Design

Conventional pipes and pipelines are designed under one of the well-established design codes that enshrine the mathematical relationship between internal pressure and the various stresses in the pipe material or limit states of failure of the pipe during installation, commissioning and operation. Required inputs to design calculations include: the pipe diameter sufficient to provide necessary flow rate, the tensile strength and corrosion resistance of the construction materials, and appropriate safety factors. The output is the wall thickness considered fit-for-purpose under that Design Code. The key Ultimate Failure Mode of such pipes remains bursting outwards when the pipe wall material can no longer resist the internal pressure.

Deepwater Pipelines

When installed in deep water, the ultimate failure mode of pipe is radically different. As a pipeline is laid into deeper and deeper water, the external hydrostatic pressure of the surrounding water increases to the point where the failure mode of the pipe is inwards collapse, instead of outwards. The Ultimate Failure Mode of deep water heavy wall pipe is structural elastic buckling of the pipe wall cross-section. It collapses in an implosive elastic buckling mode.

The depth at which a deep water pipeline collapses is sensitive to a number of factors, that are less important to the ultimate strength of conventional pipelines. The factors influencing the depth at which a deep water pipeline collapses include: ovality, small changes in material compressive strength around the circumference and through the wall thickness, changes in the compressive modulus of the steel at increasing external pressure loading, as well as wear of the semi-circular moulds used during manufacture of the pipe. Secondary forces other than the hydrostatic pressure of the deep ocean can also influence the collapse conditions. An example is the bending stresses in the pipe catenary during installation.

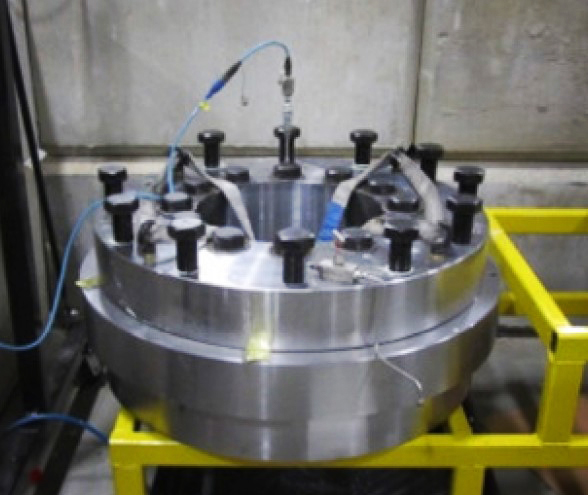

Pipe Ring Testing

Pipe ring-testing is a patented technology designed by VerdErg Pipe Technology. It measures the Ultimate Collapse Strength of deep water subsea pipeline joints by compression testing a ring cut from production pipe ends during manufacture. The pipe joint is not destroyed and remains available for project use. This contrasts with existing practice under which a full length pipe joint is destroyed by pressure collapse in a very large hyperbaric chamber.

The objectives of the VerdErg Pipe Technology test rig is to provide ring testing equipment and services that are:

- an accurate and reliable non-destructive proxy for full joint, destructive, hydrostatic pressure collapse testing,

- able to provide test results shortly after pipe manufacture,

- capable of simulating the buckling of pipe joints subjected to lateral and axial pressure, for example in the deep water pipe bend of the J-Lay pipe catenary and the “end-cap effect” during operation,

- available to Clients competitively from multiple pipe mills worldwide.

Statistical Interpretation of Pipe Ring Test Results

VerdErg Pipe Technology has used its enhanced insight into the elastic buckling of heavy wall pipe under extreme hydrostatic loading to develop and patent an improved analysis technique. This characterises numerically the collapse behaviour of a deep water pipeline from ring test results on samples of the line pipe as it is manufactured. This analysis applies a Generalised Pareto Distribution to the cohort of ring test results as defined within the Mathematics of Extreme Events.

VerdErg Pipe Technology’s analysis technique permits an effective minimum collapse pressure or depth for the pipeline to be calculated from.

Summary

Together, these two key components offer the only known way to non-destructively measure the collapse strength of a deep water pipeline.

VerdErg Pipe Technology’s patented methodology can safely justify a wall thickness reduction which lowers both the line pipe and pipeline installation costs. This significant cost saving is achieved through using less steel but more significantly, by increasing the number of pipe mills that can manufacture the pipe, and increasing the number of installation vessels that can lay the lighter pipeline. This provides the benefits of increased competition in what might otherwise have been a “Frontier Project”, liable to cost over-runs.

A less obvious saving comes from the observation that in current practice, extrapolation using DNVGL design code DNVGL-ST-F-101 is largely made from a limited data base of full joint collapse pressures. The several variables that can influence the accuracy of that extrapolation and concern about “creep” in the values of such variables during the passage of time between the collapse tests and manufacture correctly mandates that a conservative approach be used, and significant “safety factors” be adopted in the extrapolation. One inevitable consequence is that there is a natural reluctance to adopt lower-cost pipe manufactured in the newer pipe mills, typically in India and Russia but also Japan. These newer mills generally use an inherently lower-cost pipe making process called “JCOE” rather than the traditional equipment centred technique used mainly in Europe called “UOE”. The need for such conservatism is reduced when measuring the actual collapse strength by ring testing during pipe manufacture.

Detailed Discussion

Key features of VerdErg Pipe Technology’s proprietary technology include:

Several parameters influence the ultimate collapse strength of deep water line pipe. Furthermore, some of them are very difficult to measure non-destructively and they are not all independently variables. In the past, the only way to accurately assess the strength of any given joint has been to transport the whole pipe joint to one of the few laboratories worldwide that have a sufficiently large high-pressure test chamber.

However, no two deep water pipe joints are identical in detail; some collapse at lower external pressures than others. The important objective is to determine the least collapse pressure that would occur for a population of pipe joints manufactured using nominally the same method. Destructively collapsing sacrificial whole joints in this way is a slow and expensive process and does not assess the varying strength of pipe joints in the instance of their manufacture at various pipe mills. Such full body pipe collapse cannot be employed for production control during pipe manufacture because during the time taken to transport such a heavy pipe to the laboratory and undertake the test procedure, a substantial inventory of pipe would have been made which is liable for rejection in the event of a negative test.

VerdErg Pipe Technology has demonstrated that cutting a short ring off one end of pipe joints as they are manufactured and collapsing the ring, is a reliable way to non-destructively measure the collapse strength of a complete manufactured joint. Significant R&D undertaken by VerdErg Pipe Technology supports the claim for ring-testing to be a practical Non-Destructive Test (“NDT”) proxy for full-body destructive collapse testing of a complete joint.

Ring tests have been made (under license from VerdErg Pipe Technology) on samples of pipe proposed for use in several deep water pipelines. Many of these tests have been made at an early project stage to help pre-qualify pipe mills as potential suppliers of line pipe later in the project. They have also helped pipe mills to improve their product whilst avoiding the cost and logistics of full-body collapse tests.

Two examples of this development work include:

-

- Work undertaken by then TATA Steel (now Liberty Steel) in conjunction with Det Norske Veritas (DNV) in which the benefits of Light Heat Treatment (LHT) of deep water pipe were demonstrated. This seminal project quantified the increase in collapse depth of UOE pipe, as measured by ring testing (under license from VerdErg Pipe Technology). A publication is available which documents DNV’s qualification of LHT for this purpose.

- Detailed insight into the substantial ring testing program under license from VerdErg Pipe Technology, which was undertaken by C-FER, a laboratory in Edmonton, Canada, in preparation for the South Stream project.

Such early-stage ring-testing has supported the evidence of full-body collapse testing that the wall thickness calculated from the well-known DNV code OS F-101 (now the updated DNVGL-ST-F-101) is quite conservative. In fact, the DNV code was prepared with access to the early full-body collapse tests that had been performed during the design development, for example, of the Oman-India Pipeline in the mid-1990s and other early work. This conservatism rightly recognised the limited collapse strength data available at that time and also that the ultimate collapse strength of deep water pipes manufactured by one particular mill may not correspond perfectly, or may be suspected of not corresponding perfectly, with the ultimate collapse strength of nominally identical pipes made by that mill several years later, when the project has been funded and the pipe ordered after detailed design is complete. Neither may the strength of pipe from one mill correspond with nominally identical pipe made from different heats of steel at the same mill or with pipe manufactured at other mills, possibly using other manufacturing techniques.

VerdErg Pipe Technology’s ring testing technology provides for non-destructively ring-testing a statistically significant random cohort of pipe joints during the initial testing to support qualification of candidate pipe mills and later as they are manufactured by the chosen mill(s).

By non-destructively testing to determine the actual collapse strength of the pipe to be installed during manufacture, any non-compliant product can be quarantined, investigated and the cause remedied in near real-time.

Several of the relevant Publications and References make the point that any group of ring-tests have a statistical scatter reflecting the inherent variability of the ultimate collapse strength of nominally identical heavy wall pipe.

The conventional engineering approach has been adopted around the Industry of fitting these scattered data into a Normal Distribution and thereby predicting the probability of a joint collapsing at increasingly low probabilities. The one in a million or one in ten million chance of failure are referenced quite widely across many industries as an acceptable level of safety amongst investors and insurance companies. Some comfort has been gained on deep water pipeline projects, for example, from predicting that there is less than a one in a million chance of failure, projected statistically from ring-testing (and/or collapsing full joint) samples of several pipes at the pipe mill prequalification stage, early in the project.

Some concerns about ring testing had remained unanswered, however, amongst both VPTL itself and the main Stakeholders in the deep water pipeline industry. VPTL considered these concerns to be legitimate and has now addressed them, as noted in the Publications and References. The concerns included:

- It is possible to misuse the ring-testing apparatus and thereby getting invalid test results, possibly over-estimating the ultimate collapse strength of the pipe. Adoption as a test routine of VPTL’s patented Push-Out Test addresses this issue.

- A real pipeline in operation on the seabed experiences “end cap” forces that are not replicated in ring-testing. VPTL has demonstrated that this effect is marginal and is in any event largely eliminated by other second order effects acting in an opposing manner during testing using equipment validated by VPTL.

- There has not been unanimous agreement about the effect of the pipe Yield Strength on the ultimate collapse strength of a pipe. VPTL has fully evaluated this matter theoretically and has an active program to collect and publish ring test data in support of its conclusions.

- There has not been unanimous agreement about the effect on the ultimate collapse strength of a pipe of the method of manufacture (e.g. UOE or JCOE). Again, VPTL is actively gathering real ring-test data to support its expected results. As with the effect of the pipe yield strength, however, the point of adopting ring testing during manufacture is that the actual strength of the pipe to be installed is intimately included in the tests, thus taking precedence over the various slightly different predictions of anticipated strength that different Stakeholders may have made.

- During pipeline installation into deep water, it takes quite a long time for any one joint to transit from the surface to the seabed. Failure to replicate this slow application of increasing external pressure during ring testing can produce misleading results. The qualified VPTL ring test procedure will specify the correct equipment and procedures required to simulate accurately this phenomenon.

- The Normal Distribution is a notoriously unreliable tool in some circumstances where it has been invoked to predict very rare extreme events, in what are known as the “tails” of the distribution. Use of the Normal Distribution to predict extremely unlikely ultimate pressure collapse probabilities has been the subject of intensive proprietary research by VPTL. This practice of using the Normal Distribution has been found by VPTL to be invalid and that a Generalised Pareto Distribution (GPD), described in the Mathematics of Extreme Events, should be applied.One interesting outcome of applying a GDP was that a radically different shape was found for the probability density curve of ultimate collapse pressures of a cohort of ring test results. There was a near-vertical lower tail indicating that there was, in effect, an absolute minimum ultimate pressure collapse limit for the pipe being ring-tested.By Complete contrast, the tail of a Normal Distribution is asymptotic to the horizontal. This indicates a finite probability of pipeline failure in shallow water. Even though this chance of failure is very small, it is finite and greatly worrying to a non-technical investor looking for justification for what could be a multi-billion dollar investment.What VPTL has shown is that the finite chance of failure in shallow water is not a real physical occurrence but is an artificial consequence of invalidly applying the Normal Distribution. The demonstration by VPTL’s patented analysis methodology using a Generalised Pareto Distribution that there is in effect an absolute minimum collapse depth threshold is a very confidence-building outcome from the viewpoint of the non-technical Investors in, and Insurers of, any very deep water pipeline.VPTL has determined that there is a very specific reason for this comforting absolute minimum collapse strength, which provides a greatly enhanced assurance of safety and greatly improved visibility of the real safety factor provided by any selected pipe wall thickness for a given pipeline.The reason is that under the long-established codes of practice for manufacture of conventional line pipe, the ovality and tensile strength of a sample of manufactured pipes are measuredduring manufacture. Non-compliant pipes are rejected, although in practice at a good pipe mill, they are not common.Deep water line pipe is manufactured to meet the same codes of practice as conventional pipe as well as any heavy wall pipe codes such as DNVGL-ST-F-101 VPTL is proposing that for deepwater pipe, the ovality of every joint should be measured quickly during manufacture usingb laser equipment, further increasing the confidence that can be associated with inappropriately out-of-round pipes having been rejected. The effect of rejecting any unduly oval or weak pipe joints is to weed out “rogue pipes” and skew the GPD statistical model favourably into a recognition of the absolute minimum strength that actually exists and can be quantified when ring testing during manufacture is made under VPTL procedures and appropriate QA. Using a Normal Distribution completely misses this reality and gives worrying prediction of pipe failure at any water depth.